Kistler Offers New Milling Optimization Service; Reduce Vibration and Costs

In machining applications, unwanted vibrations on structures cause multiple negative effects. They can impact component quality (dimensions, surface, etc.), limit productivity, and decrease tool life -- leading to faulty parts and additional reworking as well as higher costs for materials, tools, machines and engineers. To avoid these problems, Kistler is now offering a new milling optimization service in collaboration with Productive Machines Ltd, the UK-based cutting force experts.

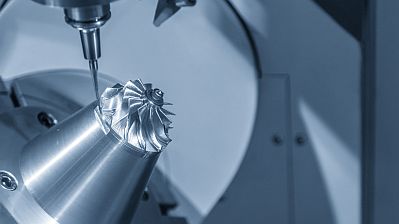

Kistler is offering a new milling optimization service that combines physical measurements and deep software analysis: benefits include improved part quality and tool performance, reduced chatter vibrations and lower costs. [Kistler Group]

The basis for this innovative service is a dynamic stiffness analysis of the machine tool. The physical optimization phase (known as the "tap test") can be accomplished with impulse hammers and accelerometers from Kistler. This is followed by an analysis of the customer's NC program, performed with new software from Productive Machines. All the acquired data is then processed to create a new NC program which, once installed, ultimately leads to better cutting performance, longer tool lifetimes and higher OEE -- to name just a few benefits.

Significant Improvements Across Diverse Applications

Although the milling optimization service has only been available on the market for a short time, customers in many industries have already discovered its major advantages.

Successful use cases include applications in the automotive, aerospace, moldmaking, precision parts and medical technology sectors.

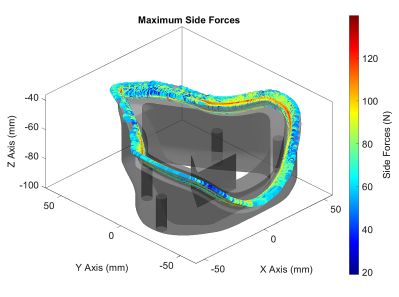

Following a dynamic stiffness analysis, a new NC program is calculated for the milling machine: this optimizes the key parameters, leading to improved overall machining performance and higher OEE. [Kistler Group]

Some examples: for a French car manufacturer facing challenges with a machining process for a gearbox housing, the optimization service provided a solution that led to shorter cycle times and reduced tool wear. Also, thanks to the new offering, an aerospace supplier based in Spain benefited from less chatter, fewer damaged parts and overall cost savings of 25 percent. And last but not least, a UK-based mill/turn specialist was able to optimize production of an aerospace part with the help of the new service: in this case, applied maximum forces decreased from 2,000 to 1,000 N and cycle times were shortened by 13 percent.

Fully Digital Delivery Available

The new milling optimization service is available either onsite (when experts from Productive Machines visit the customer) or remotely in digital form via a credit-based online platform. Customers who choose the remote option conduct the dynamic stiffness analysis themselves, and then upload the CAM files to the platform.

Want more information? Click below.

Rate this article

View our terms of use and privacy policy ::m::